Polymers Group has been cooperating with the company SABIC Innovative Plastics (formerly General Electric Plastics) for many decades in distributing technical thermoplastics - injection molding and extrusion resins. Innovative approach and the constant developing of the sales program enable us to meet the most complex requirements of our customers.

The Innovative Plastics strategic business unit of SABIC is a leading, global supplier of engineering thermoplastics with an 80-year history of breakthrough solutions and success which have been their distinctive features from the very beginning. Formerly known as General Electric Plastics (GEP) today SABIC Innovative Plastics is a company whose value is measured in billions of dollars, that operates in more than 35 countries worldwide, with more than 9000 employees. Brands Lexan, Noryl, Valoks, Ultem have been synonyms for superior technical materials in Serbia for a long time.

LEXAN resin PC virtually unbreakable

As an outstanding engineering thermoplastic, Lexan polycarbonate (PC) with its exceptional combination of features exceeds the boundaries imposed by standard materials in construction and design.

It exhibits extremely high toughness (within the temperature range from -40°C to + 100°C), durability, safety, self-extinguishing feature, excellent surface…

As a company which has patented the polycarbonate, SABIC IP can offer to its customers the vastest array of these products available in the market. You can choose among the resins more transparent than glass, colored or tinted as desired, with one of many special visual effects...

By combining specially formulated additives their features can be further enhanced (UV stability, flame retardancy, toughness, easy tool manipulation…) also available are the products with attests for flame resistance up to UL V0 (for electro-industry), food contact, medical industry and so n.

NORYL Modified PPE – hydrolytic stability and heat resistance

Noryl (amorphous blend of PPO and polystyrene), Noryl GTX (PPE and PA) and Noryl PPX (PPE blend and PP) are among the materials with superior hydrolytic stability, which makes them suitable for prolonged contact with water (pump components, etc.). They are distinguished by the exceptional chemical resistance, superior quality finishing surface, easy subsequent painting in chambers, low density and high temperature resistance - all this makes Noryl material of choice in the auto industry. There are also excellent electrical properties, self-extinguishing without the use of halogens, easy processing and low density (product weight reduction with better or the same functional properties). Special, flexible grades are ideal for making insulating lining of cables in electrical industry.

CYCOLOY – exceptionally tough and easy to process

This high impact amorphous thermoplastic blend (PC/ABS) offers the best of both worlds with excellent property balance that appeals to molders. It combines ease of processing , excellent toughness, high temperatures resistance and perfect surface appearance and can be so tailored to meet specific property requirements to help balance performance, cost and, processability. CYCOLOY resin blends provide an excellent design solution when both appearance and durability are important. Available in standard grades and biocompatible, flame retardant grades, grades suitable for galvanization, with or without glass fibers, as well as a series with high dimensional stability.

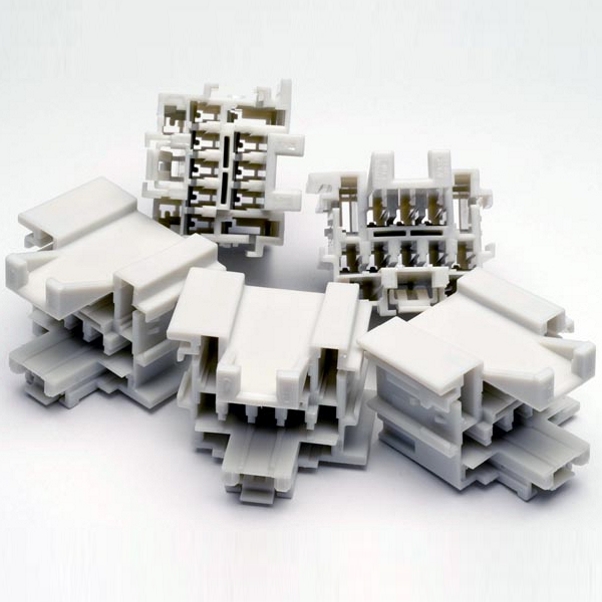

VALOX polybutylene terephthalate (PBT) – performances at request

The VALOX resin is semi-crystalline polymers based on polybutylene terephthalate (PBT) or polyethylene terephthalate (PET). VALOX resins are highly tailorable, combining heat, chemical resistance, and outstanding electrical properties with exceptionally good processability and surface appearance. This material exhibits stability in extremely wide temperature range from -40 ° C to + 140 ° C (being its RTI), it is dimensionally stable in wet conditions, flame retardant, wearproof, self-lubricating ...

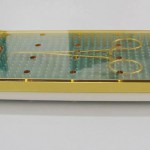

ULTEM pkolyetherimide (PEI) – material for highest temperatures

The ULTEM Resin family of amorphous thermoplastic polyetherimide (PEI) resins offers outstanding elevated thermal resistance (glass transition temperature of 217 °C and relative thermal indices (RTI) up to 180 °C)and exhibits a self-extinguishing feature achieved without additives owing to its high oxygen index (LOI 47% ). These features along with high strength, stiffness , dimensional stability make it a perfect material for the parts exposed to high temperatures in food, medical , automobile and aircraft industries… Available materials for durable applications in medical sterilizations, for contact with drinking water and so on.